Cement industry, what is needed? As we all know, China is a major producer and consumer of cement. As one of the pillar industries in the domestic economy, many enterprises are still plagued by high energy consumption. In the common production process system, fan equipment is a major energy consumer, accounting for more than 30% of the total energy consumption. This high energy consumption phenomenon severely restricts cement enterprises from reducing costs and increasing efficiency, and contradicts the concept of "second-generation cement" which emphasizes energy saving, high efficiency, environmental protection, and intelligence.

Forecast for the cement industry in 2023: stricter environmental protection, comprehensive response to the "carbon emissions" challenge, how should the cement industry answer the question? In recent years, with the increasing demand for energy-saving fans in the market, more and more high-efficiency and energy-saving fans have been developed. Once these high-efficiency and energy-saving fans are introduced, they have attracted the attention of many cement enterprises. Among them, the "Zhongjia Magnetic Suspension Drum Fan" is one of them, and its energy-saving effect has been proven. Many cement enterprises have started to plan to upgrade their existing outdated fans. Today, let's interpret the Zhongjia Magnetic Suspension Fan for cement enterprises.

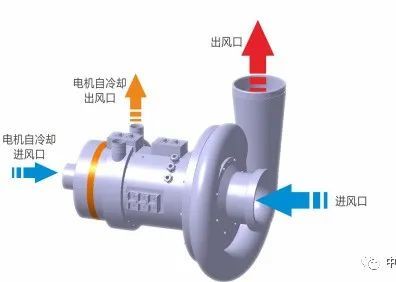

1.Working principle of the fan: The Zhongjia Magnetic Suspension High-speed Centrifugal Drum Fan adopts the direct-drive structure of high-speed permanent magnet synchronous motor, integrating the centrifugal impeller and motor drive. It detects the vibration of the rotor shaft and the spatial gap of the rotor shaft through the built-in displacement sensor, sends the obtained signals to the magnetic suspension bearing controller for conditioning, analysis, calculation, and generation of control current, and then inputs the current into the winding coil of the magnetic bearing to generate electromagnetic force, thereby achieving the suspension of the rotor shaft. The main function of the permanent magnet synchronous motor is to drive the rotation of the rotor shaft. It generates a controllable current with a frequency through the frequency converter, inputs this current into the rotating magnetic field generated by the stator of the motor, and drives the rotor shaft to rotate at high speed. The main function of the fan is to realize air blowing. The impeller rotating at high speed with the rotor shaft drives the air and does work on the air. The air enters from the inlet collector of the volute, and under the guidance and pressurization of the volute, it becomes a gas with a certain flow velocity and pressure, and finally blows out from the outlet of the volute, thereby causing the fan to blow and realize the transportation of gas with a certain pressure and flow rate.

2.Four core technologies of Zhongjia Magnetic Suspension Drum Fan:

- The first one: High-efficiency centrifugal impeller

- Designed and optimized according to the three-element flow theory, improving the efficiency of the impeller and expanding the operating range.

- The impeller material is made of high-strength alloy with strong deformation resistance. Three-element flow impeller.

- The second one: High-power high-speed permanent magnet synchronous motor

- Uses high-speed high-power permanent magnet synchronous motor.

- The motor is small in size, light in weight, and has high power density.

- The motor has high speed, up to 120,000 rpm.

- The third one: Magnetic suspension bearing

- No wear and no lubrication, can achieve high-speed operation.

- Can monitor the status of the rotor and the bearing.

- Can achieve active control and adjust rigidity/damping. Magnetic suspension bearing.

- The fourth one: Special control system

- Possesses a high-power variable frequency speed control system with complete independent intellectual property rights.

- Adjusts the motor speed by changing the output current frequency of the frequency converter, thereby adjusting the flow rate. Magnetic bearing controller.

3.High efficiency, energy saving, environmental protection, and intelligence:

- High efficiency: The maximum speed of a single magnetic suspension drum fan can reach 60,000-120,000 rpm, and a single magnetic suspension drum fan can replace multiple Roots blowers, resulting in higher efficiency.

- Energy saving: The magnetic suspension drum fan has no mechanical friction and low energy loss during operation, making it more energy-saving and electricity-saving. Compared with traditional gear-driven fans, it can save 30% of energy. Taking a 5,000-ton production line as an example, it requires about 5-6 sets of 75 kW magnetic suspension centrifugal drum fans, and each equipment can save about 300,000 kWh of electricity per year. A production line can save more than 1.8 million kWh of electricity per year.

- Environmental protection: The magnetic suspension drum fan does not require lubricating oil, and the on-site environment is clean and tidy. There is no mechanical friction during operation, greatly reducing operating noise, and it has obvious advantages compared to traditional Roots blowers.

- Intelligence: The entire control system of the fan can be controlled by a centralized display screen, and it can also be controlled remotely. Traditional fans can only obtain some operational data through on-site observation or manual detection, while the entire operation status of the magnetic suspension drum fan is intelligently detected and displayed on the screen, making it more intelligent, simple, and technological.

The magnetic suspension drum fan launched by Luoyang Zhongjia Control Technology Co., Ltd. is an innovative and upgraded product, and its energy-saving effect has been recognized by many enterprises. If you want to learn more about our products, you can contact us for consultation. Hotline: 0379-60301076.

CONTACT

US

We will reply as soon as possible and do our best to assist you. Your feedback is very important to us, and we hope to hear your voice.