The Zhongjia Magnetic Levitation Blower can be applied in various fields, mainly serving the following purposes:

1.Material gas conveying: It can be used in industries such as cement plants, chemical industry, food, medicine, and fermentation to transport industrial raw materials, dust, and food through pneumatic conveying.

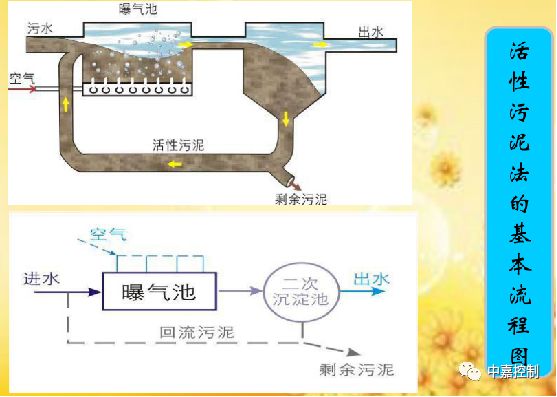

2.Aeration: It can be used for aeration in sewage treatment plants (municipal and industrial) to ensure the full contact between the biologically active substances in the sewage treatment tank and the substances in the sewage, thereby achieving the purpose of purification.

3.Oxygenation: It can be used in aquaculture to increase the oxygen content in the water by injecting air into the bottom of the fish farming ponds, thereby improving the survival rate of aquatic products.

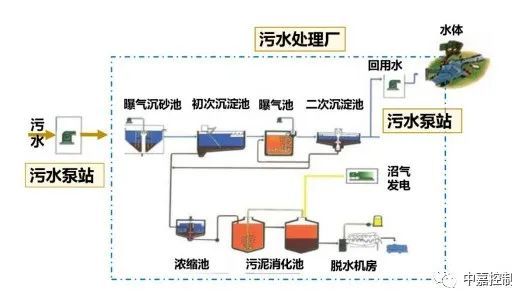

4.Desulfurization and oxidation: It can be used in industries such as paper mills, brewing, textile, dairy processing, and thermal power to achieve ultra-low emissions and reduce pollution emissions through desulfurization and oxidation.

The above are the roles of Zhongjia Magnetic Levitation Blower in industrial scenarios. Here are a few common application scenarios:

1.Application in sewage treatment plants: The magnetic levitation blower is one of the most important process equipment in sewage treatment systems, accounting for 50% of the total energy consumption of the sewage plant. Its role in sewage treatment is to aerate the water to increase the oxygen content, thereby removing iron, manganese, or promoting microbial degradation to remove oxidizable precipitates. Aeration also allows water and air to fully contact and exchange gaseous substances, removing volatile substances in water such as odors, carbon dioxide, hydrogen sulfide, etc. Aeration can also be carried out through the bottom air duct to agitate the bottom sediment and discharge it through wastewater pumps.

2.Application in power plants: In the production of power generation and metallurgical industries, in order to remove sulfur from coal and prevent the generated sulfur dioxide from entering the atmosphere and polluting the environment, flue gas desulfurization is usually used. The collected flue gas is subjected to desulfurization through gypsum wet process. The blower plays a key role in the flue gas desulfurization process by providing sufficient oxygen to ensure complete oxidation. Insufficient air volume can result in incomplete oxidation, leading to low product quality and incomplete desulfurization.

3.Application in chemical and pharmaceutical industries: The blower can be used for combustion assistance, such as blowing air into sulfuric acid plants for burning sulfur or pyrite. It can also be used in oxidation equipment for oxidizing organic waste, aerobic fermentation equipment such as blowing air into reaction vessels during the production of penicillin in pharmaceutical plants, and enhancing air convection, such as blowing fresh air into workshops with exhaust gases.

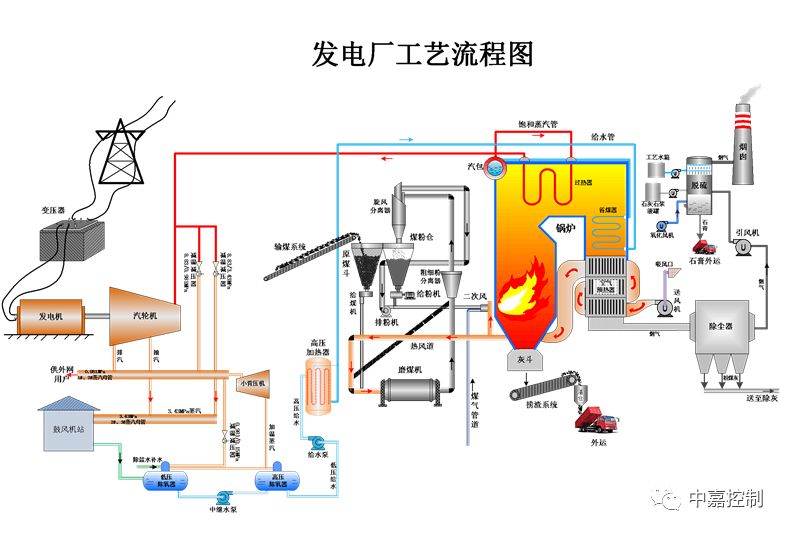

4.Application in aluminum electrolysis plants: In the production process of aluminum electrolysis, the emitted gases contain hazardous substances, specifically hydrogen fluoride and aluminum oxide dust. These gases seriously affect human health and damage the natural ecological environment. In order to avoid serious pollution caused by these harmful substances, it is necessary to concentrate and purify them to meet the national emission standards. The magnetic levitation blower is one of the main equipment in the purification treatment system.

5.Application in cement plants: The entire cement production process includes raw material preparation, raw material grinding, clinker calcination, cement clinker grinding, cement storage, and transportation processes. There are three stages where blowers are used: (1) Homogenization stage after raw material grinding, i.e., raw material homogenization silo; (2) Clinker calcination in the rotary kiln at high temperatures; (3) Cement storage and transportation, i.e., bottom blowers in the cement silo.

CONTACT

US

We will reply as soon as possible and do our best to assist you. Your feedback is very important to us, and we hope to hear your voice.