Air suspension blowers and magnetic suspension blowers are commonly used energy-saving equipment. Compared with traditional blowers, they have better energy-saving effects, are simple to operate, and are easy to install and maintain.

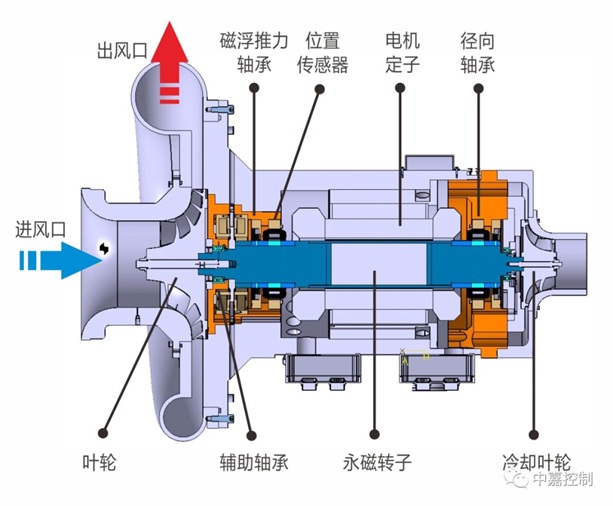

Magnetic levitation blower: It uses touch-free and mechanical conflict-free magnetic levitation bearings and a high-efficiency permanent magnet synchronous motor to directly drive the high-efficiency centrifugal impeller, which overcomes the shortcomings of traditional fans and has the characteristics of high efficiency and low noise.

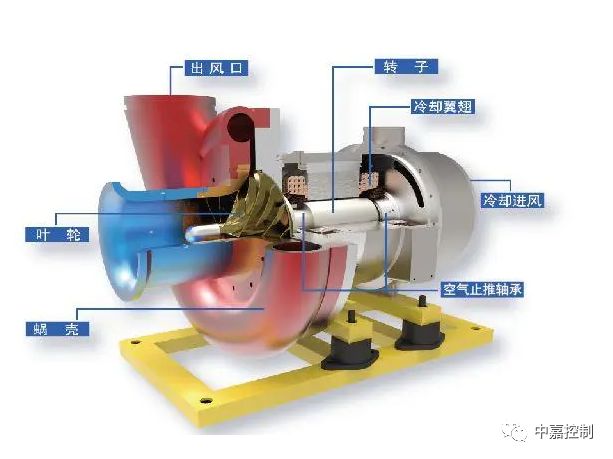

Air suspension blower: Compared with magnetic suspension blowers, air suspension blowers use air suspension bearings to use air buoyancy instead of lubricating oil. In fact, they use the surrounding air instead of lubricating oil, so they can operate at higher temperatures and high speeds.

What is the difference between magnetic levitation blower and air levitation blower?

Similarities: The core technologies of both of them adopt high-efficiency permanent magnet motors and frequency conversion system regulation. They do not require lubricating oil and have the characteristics of high efficiency, energy saving, low noise, no oil pollution, small size, and light weight.

difference:

1.Core accessories - different types of bearings used: magnetic levitation blowers use magnetic levitation bearings. Magnetic levitation bearings use electromagnetic action to make the bearings in a suspended state and then rotate, truly achieving frictionless start and can be started frequently, while air suspension blowers The principle of bearing suspension is that when the air blower rotor rotates at high speed, it will produce a dynamic pressure effect between the rotor and the foil bearing surface, forming a high-pressure air film to float the bearing. During the suspension process of the bearing, there will be a low-speed dry friction process and cannot be started frequently.

2.Difference in service life: Because the air suspension fan uses external dynamic pressure air, the main shaft has dry friction problems when the rotational speed is low, and when starting and pausing, it needs to rub the bearing and cannot start and stop frequently. Magnetic bearings use magnetic levitation to support the load, and the rotating shaft can float and move relative to each other. Through a series of precise control systems and sensors, friction or wear of the main shaft is avoided. Therefore, there is a big difference in the service life of the bearings. Under normal circumstances, the service life of air suspension bearings is generally 5-10 years, while the service life of magnetic suspension bearings is as long as more than 20 years.

3.Energy-saving effect: Since there is no mechanical friction in the magnetic levitation blower, and the two have certain parameter overlap in some aspects, in general, the magnetic levitation blower has better energy-saving effect than the air suspension blower. According to actual application data, the overall efficiency of the magnetic levitation blower is 80%, while the air levitation blower is about 75%. After calculation, under the same working conditions, a 75KW magnetic levitation blower is more energy-saving than an air levitation blower when running all year round.

In the manufacturing field, core technology is the foundation of an enterprise, and core technology with independent intellectual property rights is the "vital gate" of an enterprise. Luoyang Zhongjia Control Technology Co., Ltd. has always adhered to technology research and development, and currently has a number of key technologies with independent intellectual property rights. The magnetic levitation high-speed centrifugal blower developed by our company can save more than 30% of energy and produce a noise of 80 decibels compared with traditional blowers. It is 100% free of lubrication and maintenance-free and has a service life of more than 20 years. At present, this equipment has been widely used in sewage treatment, electronic products, pharmaceuticals, chemicals, electroplating, papermaking and many other industries.

CONTACT

US

We will reply as soon as possible and do our best to assist you. Your feedback is very important to us, and we hope to hear your voice.