- MLB Control System

- Fluid Components

- UHE-PMSM

- HEVFT

- MCSCP

- Core Competencies

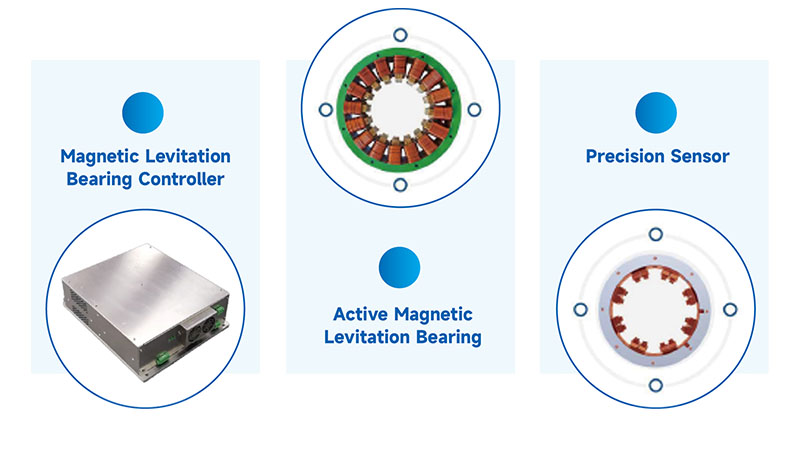

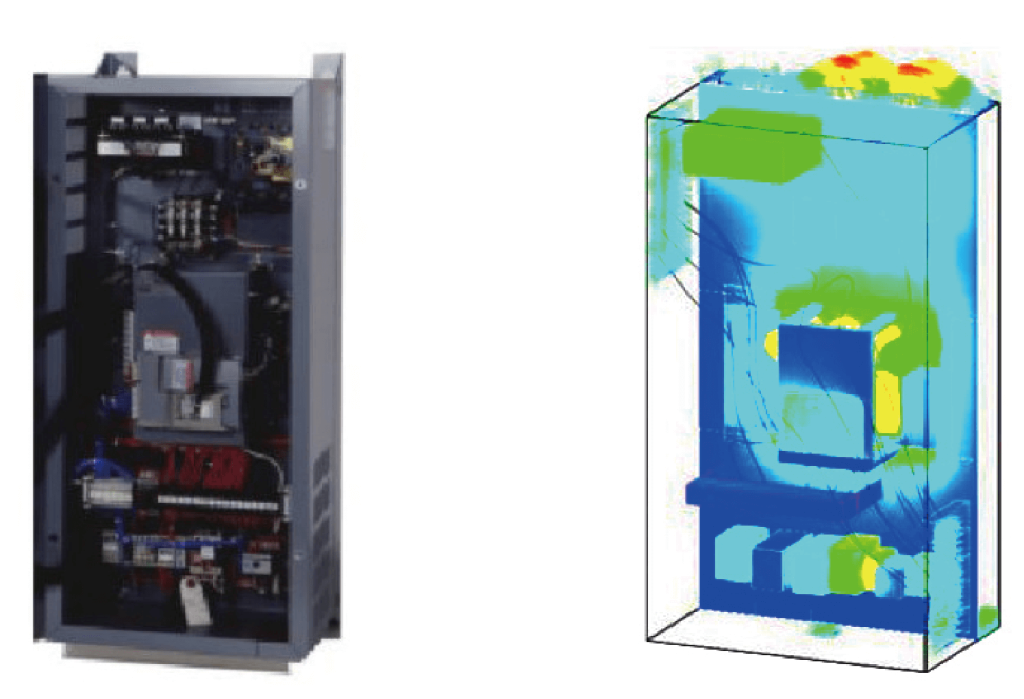

The magnetic levitation control system consists of a controller, rotor, magnetic bearing, sensor, and power amplifier. Compared with traditional mechanical bearings, sliding bearings, and oil-lubricated bearings, magnetic bearings have no mechanical contact. The rotor can achieve very high rotational speeds, offering features such as no friction, low energy consumption, high efficiency, low noise, long service life, no need for lubrication, and no pollution. These characteristics make it especially suitable for high-speed, vacuum, ultra-clean, and other special environments.

- Displacement Sensor:Detects displacement signals of the rotor.

- Controller:Processes signals through adjustment, computation, and generates control voltage signals.

- Power Amplifier:Converts control voltage signals into control current.

- Magnetic Bearing:Generates electromagnetic force to support the rotor.

- Rotor:Maintains a stable levitated and balanced position.

The principle of keeping the rotor stably levitated is that the rotor is suspended under the action of magnetic force. When the rotor is disturbed, the sensor detects the rotor's displacement reference point and sends the displacement signal to the controller. The controller's microprocessor calculates the control signal based on the detected displacement signal. Then, the power amplifier converts the control signal into control current and inputs it to the magnetic bearing. Through the coordination of these components, the magnetic levitation motor can operate stably at high speed without friction.

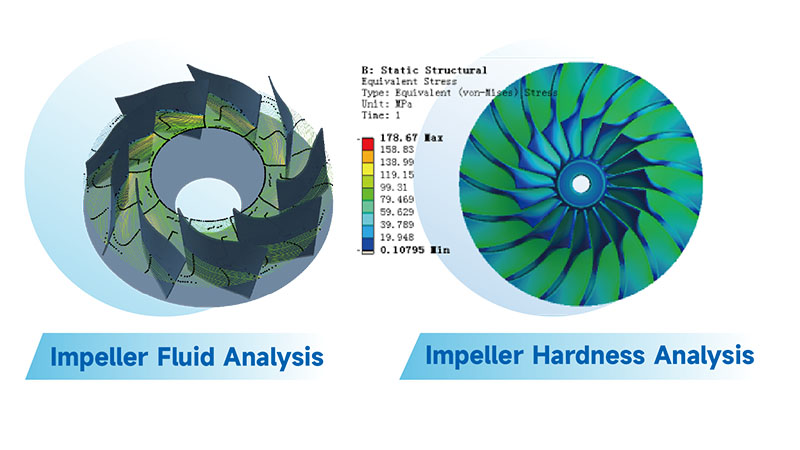

The fluid components include three-dimensional flow impellers and volutes. The impellers are made of high-strength alloy through five-axis machining as an integrated unit, ensuring sharpness, strength, and reliability. The impellers adopt three-dimensional flow theory and optimized designs of high-efficiency volutes, making the equipment suitable for gas transmission and compression applications across various industrial fields.

The working principle of the 3D impeller is based on the control of dynamic balance and fluid flow during rotation. When fluid enters the inlet of the 3D impeller, the guide vanes regulate its flow direction and velocity. Under the rotational action of the impeller blades, the fluid is compressed and accelerated, eventually exiting through the impeller outlet. Compared with traditional impellers, the 3D impeller offers higher efficiency and a wider range of applications. Its simple structure allows for better control of the fluid's flow direction and velocity, making the compression and acceleration of the fluid more uniform and stable. In practical applications, the use of the 3D impeller can significantly improve the performance and efficiency of equipment while reducing energy consumption and waste.

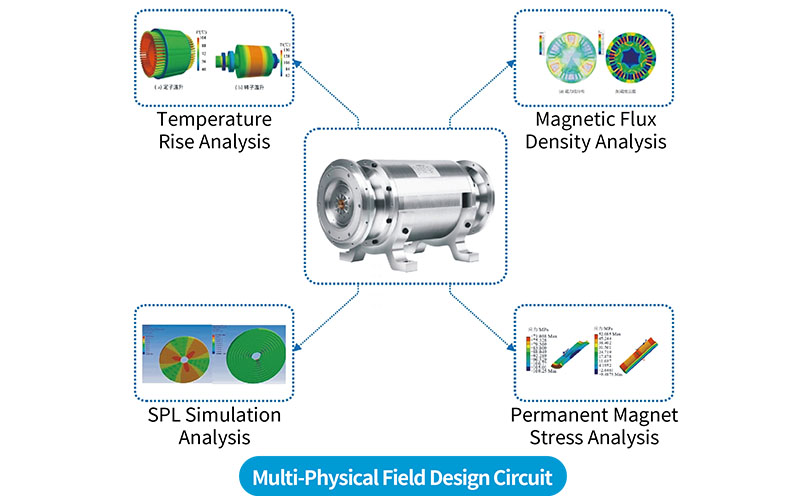

Multi-physical field design circuit is used in the design of the motor, fully considering the interaction between physical fields. The ultra-efficient permanent magnet synchronous motor is directly connected to the three-dimensional impeller and the cooling fan, ensuring high efficiency and zero transmission loss.

These advantages make the permanent magnet synchronous motor perform well in many application scenarios, especially in situations requiring high-efficiency energy conversion and compact design. Its service life is more than 20 years.

In the operation process of a high-efficiency frequency converter, the alternating current (AC) power source is first rectified into direct current (DC) power. It is then converted back into AC power of different frequencies through an inverter circuit to meet the speed requirements of various electric motors. This adjusts the motor's speed and power output, ensuring the stable operation of the system.

- Precise frequency and voltage control ensures compliance with the stringent requirements for the power parameters of the magnetic levitation system.

- Efficient energy conversion reduces energy losses and enhances the overall system efficiency.

- Quick dynamic response enables the system to rapidly adapt to changes in the load of the magnetic levitation system, ensuring its stability and reliability.

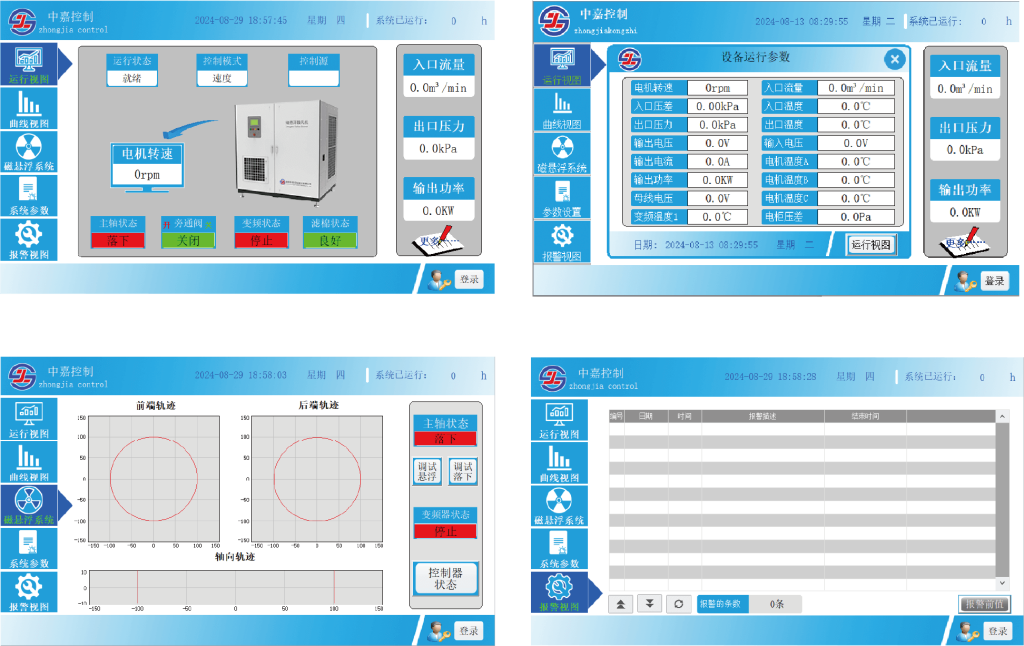

The main control system enables local control via a touchscreen and remote control through a centralized control center. By collecting and processing data from frequency converters, magnetic levitation bearing controllers, temperature, pressure, and flow sensors, it achieves automatic control and status monitoring of equipment. The operating data is displayed in real-time on the touchscreen.

Advantage

- Core technology is independently developed, controllable, and reliable.

- Intelligent control with multi-layer protection effectively prevents abnormal conditions such as motor stalling, vibration, and shutdowns.

- Combines anti-interference hardware and software for reliable and stable operation.

- Remote interface enables remote control, reducing the frequency of on-site inspections by technical personnel.

- Easy operation with a user-friendly human-machine interaction interface.

- Alarm information and recording interface.

Magnetic levitation Cloud Platform Management System Magnetic levitation Cloud Platform Management System, adopts advanced cloud computing technology and a micro-services architecture. By integrating low-latency multi-module collaboration and stable Internet of Things (IoT) technology, it enables real-time cloud-based monitoring and control of the equipment. Each module's operational data is monitored in real time, and operational status alarms are promptly pushed, providing intelligent management functionality. While ensuring the long-term stable operation of the equipment, the system reduces usage and maintenance costs. Through big data analysis, it enhances predictive capabilities and identifies potential instability factors in the equipment. This minimizes operational risks in magnetic levitation applications, ensuring the highly efficient and stable operation of the customer's integrated system.

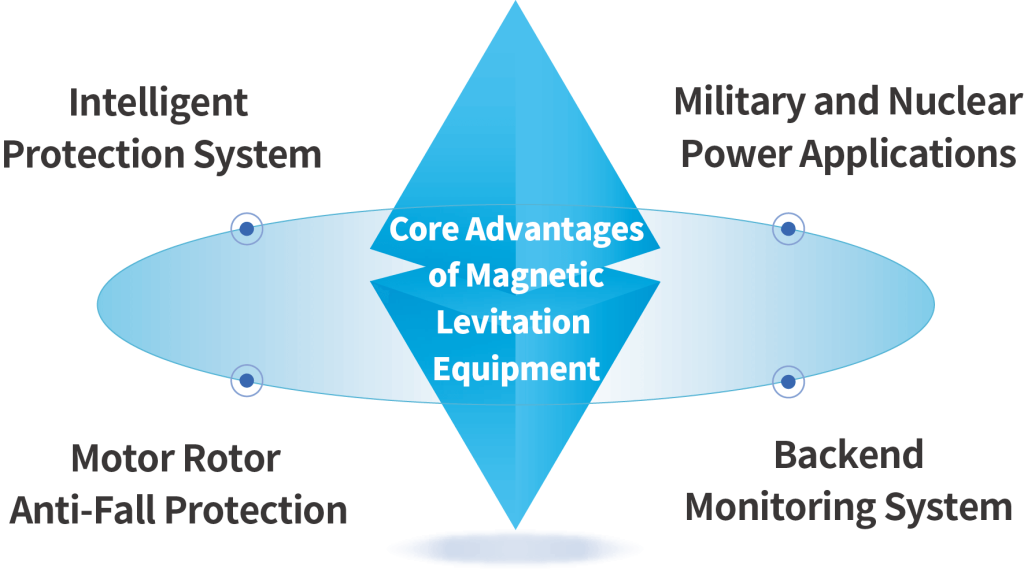

Intelligent Protection System

The intelligent protection system includes motor over-temperature protection, motor power protection, and misoperation protection. These protective functions work together to ensure the safe and stable operation of the equipment, providing reliable safeguards for various application scenarios.

Military and Nuclear Power Applications

Magnetic levitation technology relies on its high energy efficiency, precision control, high-speed operational capability, low noise, and oil-free advantages. These features ensure that the equipment is suitable for special fields such as military and nuclear power applications.

Backend Monitoring System

The backend monitoring system primarily focuses on data collection, analysis, processing, fault prediction, and maintenance. By analyzing the data, customers can monitor the system’s real-time status, identify abnormal changes or potential issues such as slight positional deviations or speed wave fluctuations, and achieve early warning and proactive interventions.

Motor Rotor Anti-Fall Protection

Motor Rotor Anti-Fall Protection

- Motor Self-Power Generation

- Dual Power Supply

- Bearing Protection

- Control Protectionof the Main System

The integrated four-layered motor protection system ensures the magnetic levitation equipment remains operational during abnormal power outages or unexpected events, preventing sudden rotor drops and avoiding potential damage to the equipment.