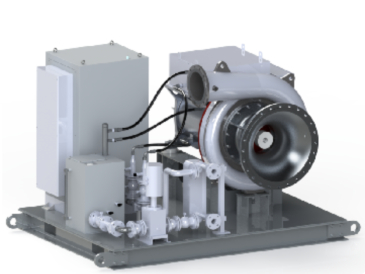

The magnetic levitation blower is a new type of efficient, energy-saving, and environmentally friendly air supply equipment that incorporates magnetic levitation bearing technology and high-speed motor technology into traditional blowers. The magnetic levitation blower uses a high-speed permanent magnet synchronous motor directly connected to an efficient three-element flow energy-saving impeller, combined with magnetic levitation bearing technology. Compared with traditional blowers, it saves 30% to 50% energy due to the absence of traditional bearing friction losses, reduces noise from 130 decibels to below 85 decibels, requires no maintenance (except for dust screens), and has a service life of over 20 years, greatly reducing user operating costs.

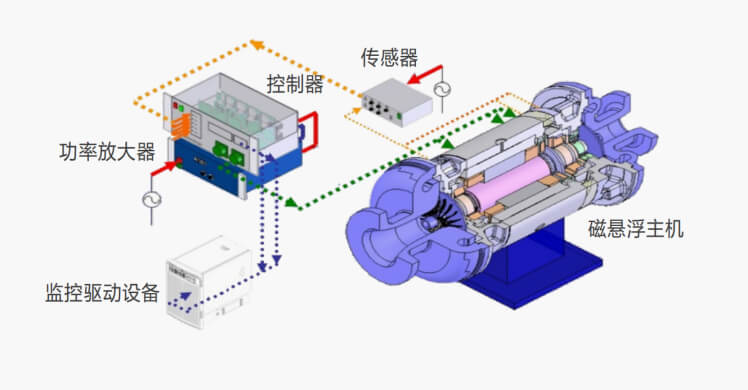

The electrical control system of the maglev high-speed blower adopts a PLC+touch screen control mode. By collecting and calculating data from the frequency converter, maglev bearing controller, temperature, pressure and flow sensors, the automatic control and operation status of the blower are monitored. The touch screen displays the motor speed, fan flow rate, motor coil temperature, outlet temperature, inlet temperature, inlet pressure, cabinet pressure difference, outlet pressure in real time Data and parameters such as fan power and working current.

In addition to providing "local" control mode, the blower also has a "remote" control interface to meet the needs of the upper control system in the central control room for remote start stop control of the blower and real-time monitoring of operating parameters and status.

The noise has decreased from 130 decibels to 85 decibels

Pure compressed air is absolutely oil-free

Local/remote, control monitoring, automatic diagnosis

No need for personnel to build a foundation

No need for vibration monitoring

With a service life of over 20 years

Regular replacement of dust removal net

More than 30% energy saving compared to Roots fans, with a two-year return on costs

| Model | Rated power (kW) | Rated speed (rpm) | Rated flow rate (m ᶟ/min) | Rated pressure (KPa) | Overall size L * W * H (mm) | Air outlet diameter |

| ZJG-03740 | 37 | 30000 | 43 | 40 | 1377* 1365* 1608 | DN125 PN10 |

| ZJG-03780 | 21 | 80 | ||||

| ZJG-03740 | 55 | 42000 | 43 | 40 | DN200 PN10 | |

| ZJG-03780 | 21 | 80 | ||||

| ZJG-03740 | 75 | 30000 | 43 | 40 | ||

| ZJG-03780 | 21 | 80 | ||||

| ZJG-03740 | 110 | 43 | 40 | 1618* 1320* 1850 | ||

| ZJG-03780 | 21 | 80 | ||||

| ZJG-03740 | 150 | 25000 | 43 | 40 | 1618* 1320* 1850 | DN300 PN10 |

| ZJG-03780 | 21 | 80 | ||||

| ZJG-03740 | 220 | 20000 | 43 | 40 | ||

| ZJG-03780 | 21 | 80 | ||||

| ZJG-03740 | 300 | 17500 | 43 | 40 | 2115*1630*2305 | |

| ZJG-03780 | 300 | 21 | 80 |

The magnetic levitation blower3

The magnetic levitation blower

The magnetic levitation blower5

The magnetic levitation blower

The magnetic levitation blower2

The magnetic levitation blower

Magnetic levitation electronic control system

Military application

We will reply as soon as possible and do our best to assist you. Your feedback is very important to us, and we hope to hear your voice.